Luwa Air Engineering Marks 90 Years with Sustainable Innovations at ITMA ASIA + CITME 2025

Celebrating 90 years of innovation, Luwa Air Engineering will showcase its latest sustainable air engineering solutions at ITMA ASIA + CITME 2025 in Singapore. From intelligent control systems to energy-efficient carbon fiber fans, Luwa continues to set industry standards in climate control, filtration, and air handling for textile manufacturing worldwide.

Luwa Air Engineering at ITMA ASIA + CITME 2025, Singapore

Luwa is participating in ITMA ASIA + CITME 2025, being held in Singapore this year. This event offers the perfect platform to highlight innovative technology, sustainable systems, and futuristic innovations that reflect Luwa’s unwavering commitment to connectivity, process efficiency, energy conservation, and sustainability.

90 Years of Experience | What It Means to the Textile World

Since starting in 1935, Luwa has set the pace for how air should be controlled in textile factories, always changing to meet the needs of the global market. Over these year Luwa brings:

- Deep Industry Insight: With operations across continents and decades of collaboration with textile manufacturers, Luwa has developed unmatched expertise. This means custom solutions that understand every detail of textile processes, from fiber to fabric.

- Proven Reliability: Successful installations across textile mills globally is a testament to Luwa’s reliability, quality engineering, and service excellence. Customers trust Luwa for systems that last, work the same every time, and perform well, no matter the size or difficulty of the job.

- Continual Innovation: At Luwa, innovation is not just a one-time thing, it is how we work every day. Over the years, Luwa has consistently introduced groundbreaking technologies that address real-world challenges, including energy optimization, dust & waste management, and digital control systems.

- Sustainability Leadership: Long before sustainability became popular, Luwa has been developing systems that minimize environmental impact while enhancing production efficiency. Today, our solutions contribute to greener, cleaner, and more compliant textile production environments.

Showcasing Luwa’s Product Portfolio

At ITMA ASIA + CITME 2025, Luwa will highlight its wide range of solutions designed to enhance air quality, machine performance, product output, and worker well-being across all stages of textile production. Luwa offers:

- Waste Collection Systems: Systems that quickly and easily remove fibers and dust to keep machines running smoothly and keep the work area clean.

- Dust Filtration Units: High-power systems that catch fine textile dust, making the factory safer, cleaner, and improving product quality.

- Machine and Room Cleaning Systems: Automatic cleaning and vacuum systems that cut down on machine downtime to make your equipment last longer.

- Humidification and Cooling Systems: Systems that keep the right amount of moisture in the air, making fiber quality better and prevents yarn breakage.

- Air Distribution Systems: Designed to move air and control temperature evenly for comfortable workers and stable production.

- Control Engineering (Luwa Digital Solutions): Modern digital control systems that allow for remote access, spot problems before they happen, and monitor energy use.

- Air Handling Units (AHUs): Custom units for cooling, heating, adding moisture, and cleaning the air. They are designed to save energy and are easy to maintain.

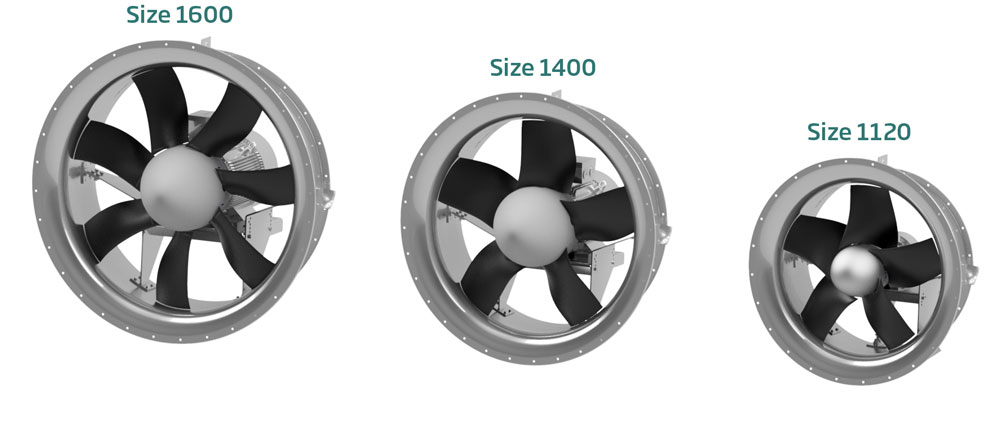

- Fans: Fans that are light, offering high airflow, using less energy, and built to last in tough textile environments.

Luwa is excited to introduce two next-gen innovations at ITMA ASIA + CITME 2025:

1. Carbon Axial Flow Fan B800CF

Built for amazing performance, the B800CF is a very efficient fan that uses carbon fiber blades for strength that is also super light. Key features include:

- Exceptional airflow efficiency

- Low energy consumption

- Reduced operational noise

- Corrosion-resistant build for long life

- Lower vibration and enhanced balancing

Carbon Axial Flow Fan B800CF is perfect for textile areas that are humid, dusty, or high-speed, offering a sustainable airflow solution that creates big energy savings.

2. Luwa Digital Solutions

A complete digital ecosystem to monitor and control your textile plant’s air engineering systems. Key highlights include:

- Real-time dashboards for energy, temperature, humidity, and machine uptime

- IoT-enabled controls for predictive maintenance

- Remote accessibility and cloud-based analytics

- Custom alerts and operational insights

- Optimized integration with plant-level ERP and PLCs

Digital Solutions moves plant automation forward, giving you total view and control while making sure production is at its peak and the factory runs sustainably.

Why Visit Luwa at ITMA ASIA + CITME 2025?

Booth No.: H3-A202 | Dates: 28–31 October 2025 | Venue: Singapore Expo

Whether you are a mill owner, plant operator, engineer, or consultant, Luwa's booth is the place to explore the future of textile air engineering. Here is what you will find:

- Discover innovative, future-ready air engineering technologies

- Live demo of the B8600 carbon fan

- Interact with global experts and engineers

- Learn how to improve energy performance, cut costs, and enhance worker safety

- Understand tailored solutions for spinning, weaving, knitting, dyeing, and finishing

Join Luwa at ITMA ASIA + CITME 2025 and experience how our innovations continue to shape the future of sustainable and efficient textile manufacturing