Axial Flow Fans with Carbon Fibre Blades

Introducing the next generation of energy-efficient, high-performance axial flow fans designed specifically for the textile industry. The Luwa B800CF series axial fans represent a breakthrough in fan technology—delivering reduced power consumption, higher aerodynamic efficiency, lighter weight, and significantly lower noise levels.

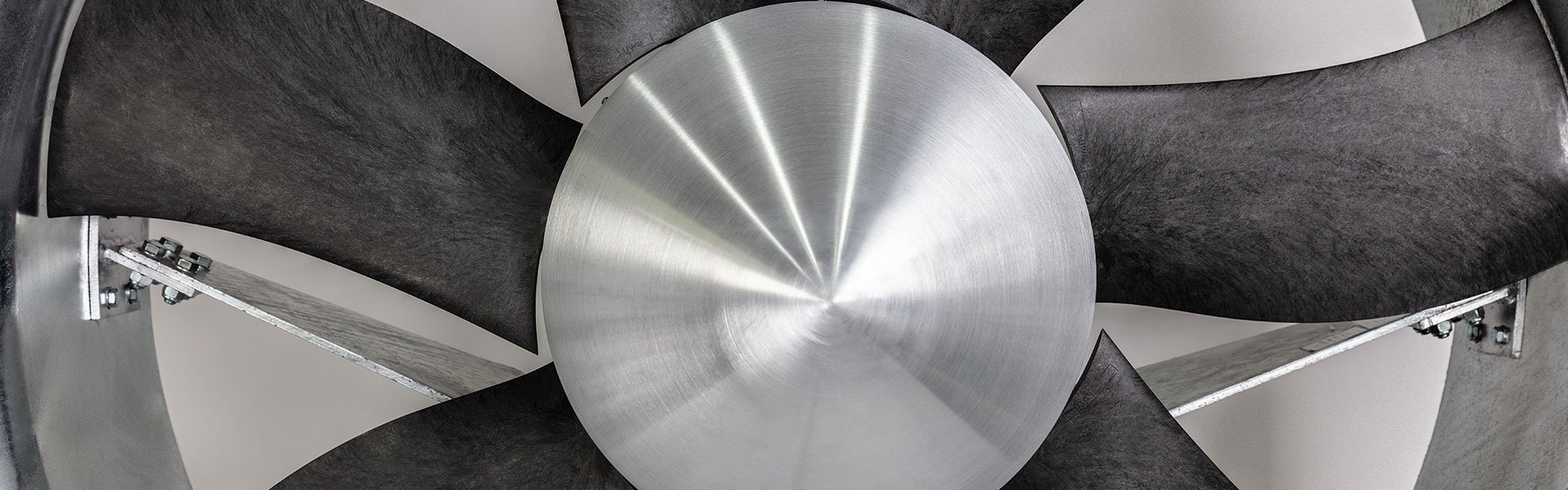

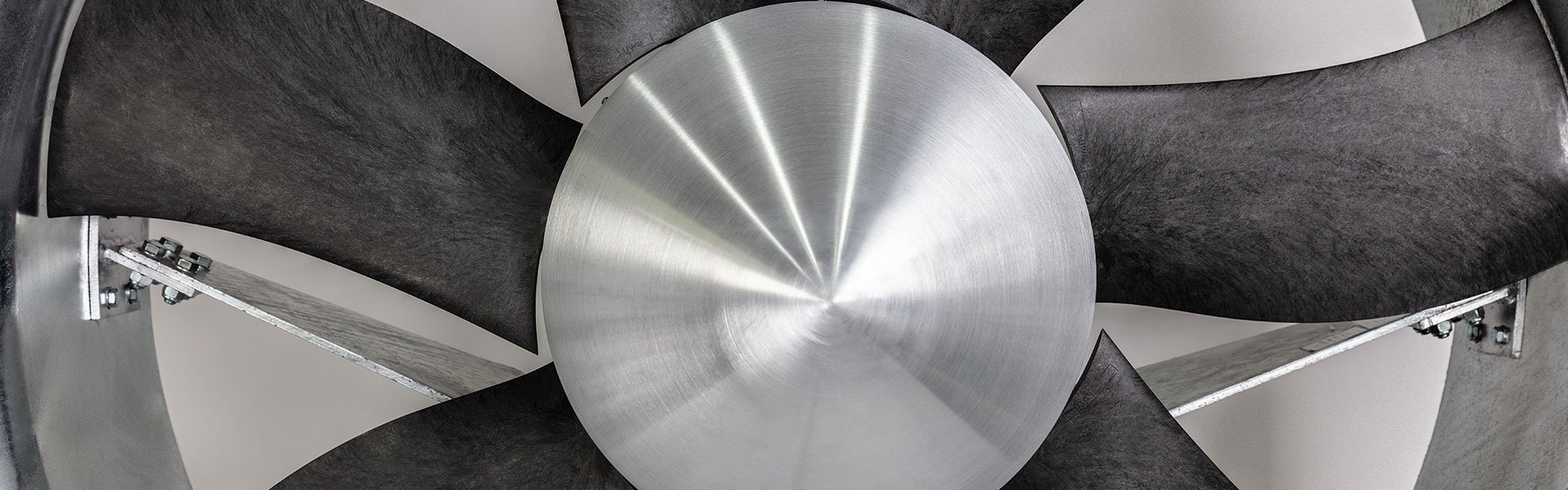

Engineered with precision and backed by Luwa’s legacy of innovation, the B800CF fans are equipped with impellers made from Hybrid Long-Carbon Fibre-Compound (LCF). This state-of-the-art material unlocks new possibilities in design, durability, and performance.

Why Carbon Fibre?

The fan blades of the Axial Flow Fan B800CF are constructed using very light yet incredibly strong Long-Carbon Fibre-Compound (LCF). This advanced material offers several advantages over conventional aluminum fans:

- Enables larger and wider blades with lower overall weight

- Reduces mechanical stresses, enhancing durability

- Provides a greater aerodynamic surface, improving airflow

- Supports innovative blade designs with thinner leading and trailing edges

Energy Efficiency That Impacts Your Bottom Line

- In a spinning mill, axial fans account for up to 55% of the total electrical energy consumption.

- In a weaving mill, this figure can reach as high as 75%

Recognizing this, Luwa developed the B800CF axial fan series—offering next-generation fan technology that reduces electrical consumption without compromising performance.

Features of the Luwa Axial Flow Fan B800CF

Discover the engineering behind the innovation:

- Advanced Carbon Fibre Blades: Constructed from a hybrid carbon fibre composite, these blades offer an excellent strength-to-weight ratio. The lower weight enables the use of larger and wider blades without increasing the motor load. This design improves both efficiency and airflow performance.

- Aerodynamic Sickle-Shaped Blades: The blades are curved in a sickle shape to reduce turbulence and drag during rotation. This design ensures smoother airflow, enhancing overall performance while significantly reducing operational noise.

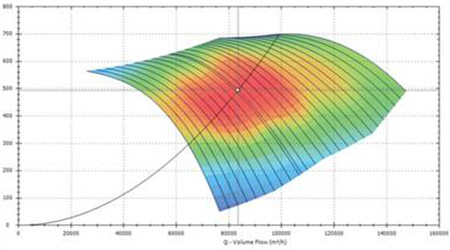

- Wider Operating Range: These fans perform efficiently even under dynamic conditions such as aging filters, fluctuating machine speeds, or pressure variances in the duct. This flexibility ensures stable performance across all operational scenarios in textile mills.

- Adjustable Blade Pitch Angle: Each blade is mounted to allow pitch angle adjustments at the time of installation. This allows fine-tuning based on required airflow and static pressure—ensuring the perfect balance between performance and energy use.

- Precision Injection Moulding: The blades are produced using advanced injection moulding techniques. This process ensures a thin, uniform edge and a smooth aerodynamic surface, significantly reducing air resistance and improving flow dynamics.

- Optimized Hub Design: The hub is engineered to work seamlessly with the lightweight blades, reducing the overall fan weight by over 60% compared to aluminum fan assemblies. The lighter weight reduces motor strain and energy consumption, while also simplifying installation and handling.

- Seamless Retrofit Capabilities: The B800CF fan is designed to be directly installed into existing Luwa systems, minimizing the need for structural modifications. This facilitates quick upgrades and system enhancements with minimal disruption.

- Noise-Reduction Engineering: Every aspect—from the aerodynamic shape to the material resonance properties—has been optimized to suppress noise. The result is a quieter working environment, particularly beneficial in spinning and weaving areas.

- Tailored for Textile Applications: The fan is designed to meet the airflow and pressure demands specific to the textile industry, including spinning and weaving sections. It provides high output with lower power input, optimizing mill energy profiles.

- Corrosion-Resistant and Durable: The materials used in the fan construction resist corrosion from humid, dusty environments typical in textile facilities, ensuring long-term reliability and performance.

- Eco-Conscious Design: The carbon fibre components are mostly recyclable, aligning with Luwa’s commitment to sustainable engineering and responsible manufacturing practices.

- Fan Selection Software: Luwa provides advanced selection software that allows precise configuration of fans based on blade pitch, required airflow, static pressure, and fan size—ensuring peak performance tailored to your plant’s needs.

Benefits of the Luwa Axial Flow Fan B800CF

Choosing the B800CF means investing in long-term operational excellence and energy savings. Here are the key benefits:

- Up to 12% Energy Savings: Achieved through lightweight carbon fibre blades and aerodynamically optimized design that reduces resistance and improves flow.

- Lower Noise Emissions: The unique blade profile and carbon fibre construction help in absorbing vibrations and reducing dB levels, creating a more comfortable work environment.

- Lightweight Construction: Enables easier handling, faster installation, and reduced load on motors and structures.

- Longer Service Life: Durable carbon fibre blades last longer than traditional aluminum, offering better return on investment through reduced maintenance and replacement costs.

- Customizable Performance: Thanks to adjustable blade pitch and available software tools, performance can be tailored precisely to meet specific airflow and static pressure requirements.

- Future-Ready Upgrade: Designed to fit seamlessly into existing Luwa systems, B800CF enables easy retrofitting, allowing textile mills to modernize operations with minimal investment.

- Improved System Efficiency: The advanced aerodynamic profile of the blades increases airflow per kW, helping to improve the overall system performance and reduce operational costs.

- Safety and Reliability: Precision manufacturing and robust materials reduce failure risk, providing safe and consistent operation in demanding textile environments.

- Eco-Friendly Design: Recyclable materials and energy-efficient operation support sustainability initiatives, reducing the environmental impact of your operations.

Engineering & Technical Collaboration

- Fan blade development was conducted in collaboration with renowned expert Prof. Th. Carolus, ensuring aerodynamic superiority.

- The use of Luwa’s selection software guarantees optimal matching of fan type, size, and pitch to suit precise system requirements.

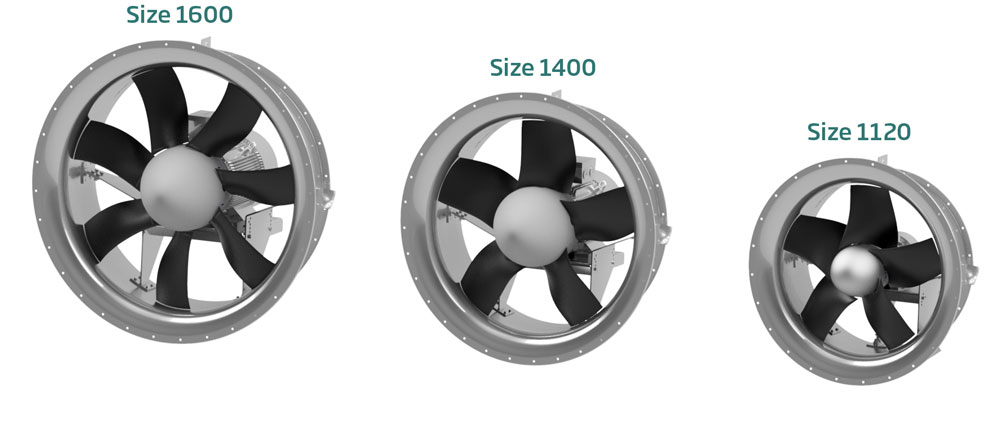

- Available with 7 fan blades, housing, and floor support, the B800CF is built for complete integration and scalable performance.

Materials and Manufacturing Process

The impellers are produced using a novel injection molding process under heat and pressure, transforming LCF pellets into durable, aerodynamic blades. This ensures:

- High dimensional accuracy and aerodynamic precision

- Thinner leading and trailing edges for superior airflow

- Excellent finish and surface quality for reduced drag

- Lighter overall design that minimizes structural load and motor power draw

The fan’s hub and overall assembly are optimized to be lighter and more robust than conventional models, enhancing both energy savings and mechanical reliability.

Sustainability Through Recycling

The carbon fibre waste generated during manufacturing is repurposed into high-quality reinforced plastic materials used in various applications. These include:

- Thermoplastic extrusion processes

- Flat carbon fibre mats for automotive or structural uses

- Recyclable composites being explored for broader industrial use

Luwa supports ongoing R&D in industrial-scale recycling of carbon fibre waste and aims to align all fan systems with sustainable manufacturing principles.

CASE STUDY – GEBR. OTTO GMBH & CO. KG

- Customer: Gebr. Otto GmbH & Co. KG

- Location: Balzheim, Germany

- Sector: Textile Industry

Overview

Gebr. Otto GmbH & Co. KG has been a prominent name in the textile industry for over a century, known for precision and innovation in premium yarn production. To improve energy efficiency, the company partnered with Luwa to modernize its ventilation system.

Challenge

The plant featured a well-maintained, yet aging ventilation system equipped with a 55 kW motor driving the original impeller. Despite functioning reliably, the system exhibited high energy consumption and limited flexibility. Energy monitoring revealed an average power draw of 43.3 kW, prompting the need for a smarter, more energy-efficient upgrade. Otto was eager to reduce energy usage, enhance system performance, and improve long-term reliability.

Solution

To address the challenge, Luwa introduced its advanced B800CF Axial Flow Fan, featuring carbon fibre impeller blades designed for optimal aerodynamic performance. The lightweight nature of carbon fibre reduces motor load, while the adjustable impeller angle enables fine-tuned airflow control tailored to process requirements.

Key Measures:

- Installation of the B800CF impeller with optimized blade geometry

- Precision adjustment of impeller angle to match the ideal operating point

- Replaced the 55 kW motor with a more efficient 45 kW motor

Results

- Over 12% reduction in energy consumption

- Power savings of more than 5 kW

- Annual savings of approx. EUR 7,000

- Reduction of nearly 14 tons of CO₂ emissions per year

This remarkable outcome not only enhanced operational efficiency but also helped Otto strengthen its sustainability goals, providing a measurable environmental benefit.

Customer Testimonial

“We were impressed by the tangible energy savings and the environmental benefits achieved with Luwa’s solution. The reduction in energy consumption and CO₂ emissions exceeded our expectations and provided a compelling case for modernizing our equipment.”

— Oliver Kächler, Authorised Signatory / Operations Manager, Gebr. Otto GmbH & Co. KG

Disclaimer

This information is compiled with the utmost care and to the best of our knowledge. However, we accept no liability for typographical errors or technical inaccuracies. Images are for illustrative purposes and may depict optional equipment not included in the standard configuration. Specifications and scope of delivery may vary depending on system configuration. We assume no responsibility for the current validity, accuracy, or completeness of the information provided. Any claims for damages based on the use or distribution of this information are excluded, even if the information is incorrect or incomplete. All data provided is non-binding.